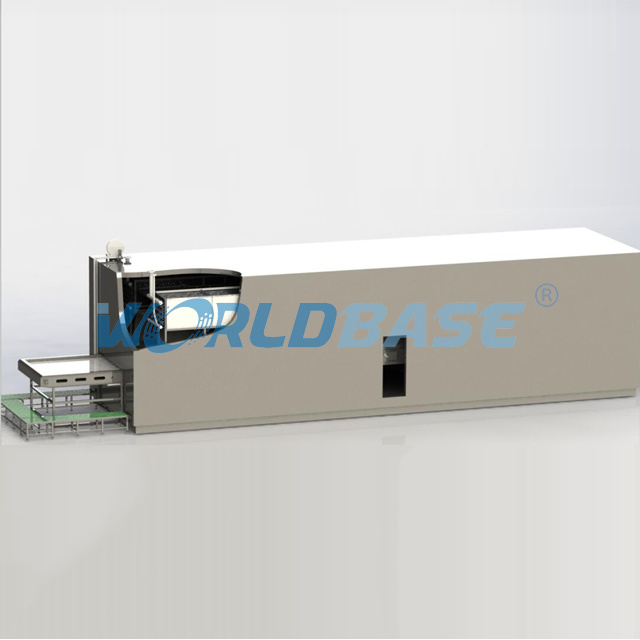

Super-jet Mesh Belt Tunnel Freezer: Efficient, Uniform & Hygienic Food Freezing

Date:

2025-12-30

In conclusion, the Super-jet Mesh Belt Tunnel Freezer represents an advanced, high-performance solution for modern food processing.

In the fast-paced food processing industry, efficiency, consistency, and product quality are critical to staying competitive. The Super-jet Mesh Belt Tunnel Freezer has emerged as a leading solution, designed to meet the growing demand for rapid and uniform freezing of various food products. Whether in seafood, bakery, meat, or prepared meals, this advanced tunnel freezer offers precise temperature control, high-speed freezing, and a hygienic design, helping manufacturers optimize production and maintain product quality. Its innovative mesh belt system ensures even air circulation, reducing freezing time and improving overall energy efficiency.

The key advantage of the Super-jet Mesh Belt Tunnel Freezer lies in its advanced mesh belt design. Unlike traditional conveyors, the open mesh structure allows cold air to circulate above and below the product, ensuring complete and uniform freezing. This minimizes cold spots or uneven freezing, which can compromise product quality and shelf life. The high-speed air jets of the Super-jet system accelerate the freezing process, preserving texture, flavor, and nutritional content. For delicate items such as seafood fillets, fruit pieces, or baked goods, the gentle yet rapid freezing prevents ice crystal formation that can damage the product, delivering superior final results.

Efficiency and energy savings are another significant benefit of the Super-jet Mesh Belt Tunnel Freezer. Its optimized airflow design reduces energy consumption compared to conventional freezing methods. The fast freezing cycle not only shortens production time but also allows manufacturers to increase throughput without additional labor or equipment. For companies operating under tight deadlines or high-volume requirements, this freezer provides the flexibility to meet demand while maintaining consistent quality. Reduced freezing time also decreases storage requirements, allowing for better space utilization and logistics management.

Hygiene and safety are central to the Super-jet Mesh Belt Tunnel Freezer design. Constructed from high-quality stainless steel and corrosion-resistant materials, the system is easy to clean and maintain, meeting strict food safety standards. The open mesh belt allows easy inspection and cleaning between production cycles, preventing bacterial growth and cross-contamination. For food processors aiming to comply with HACCP or ISO food safety certifications, the Super-jet system provides a reliable, compliant solution that supports safe and efficient production.

The versatility of the Super-jet Mesh Belt Tunnel Freezer extends across multiple food sectors. In seafood processing, it freezes fillets, shrimp, and shellfish quickly while maintaining natural texture and flavor. In bakery operations, pastries, dough pieces, and ready-to-bake products retain shape and quality. Prepared meals and frozen snacks benefit from uniform freezing, ensuring even reheating and optimal taste for end consumers. Its modular design also allows easy integration into existing production lines, making it suitable for both small-scale and large-scale operations.

A critical pain point for food manufacturers is the risk of inconsistent freezing, which can result in product waste, reduced shelf life, and compromised taste or texture. The Super-jet Mesh Belt Tunnel Freezer addresses these challenges by combining rapid freezing with uniform airflow distribution, ensuring every item is frozen to specification. Another common challenge is the high energy cost of freezing operations. By optimizing airflow and minimizing freezing time, the Super-jet system significantly reduces energy consumption, lowering operating costs while maintaining high output. Maintenance and downtime are additional concerns for production lines. The simple design, durable construction, and easy-to-clean mesh belt reduce maintenance requirements and minimize production interruptions.

Several real-world cases highlight the value of the Super-jet Mesh Belt Tunnel Freezer. A large seafood processor reported a 30% reduction in freezing time while maintaining product quality, resulting in increased throughput and reduced energy consumption. A bakery integrated the Super-jet system into its line, achieving uniform freezing of pastries without deformation, ensuring high customer satisfaction. Prepared meal manufacturers benefited from the freezer’s precise temperature control, reducing product defects and improving shelf life, ultimately enhancing brand reputation.

In conclusion, the Super-jet Mesh Belt Tunnel Freezer represents an advanced, high-performance solution for modern food processing. Its unique mesh belt design, rapid and uniform freezing capability, energy efficiency, and hygienic construction address key industry challenges. Manufacturers can achieve higher throughput, consistent product quality, and compliance with stringent food safety standards while optimizing production costs. Whether for seafood, bakery, prepared meals, or frozen snacks, the Super-jet Mesh Belt Tunnel Freezer delivers superior results, making it an indispensable asset for food processors aiming for efficiency, quality, and reliability in a competitive market.